Tower Crane

What is a tower crane and how does it work?

What is Tower Crane? Its other name is tower crane and it has the ability to lift heavy objects. You see tower cranes a lot in the city and during the construction of buildings.

Devices higher than a building to be able to lift the load up to the roof of the building. In fact, it is a giant balance lever, and this device is able to move the load in three directions x, y, and z, so to speak, it has the ability to move the load in 360 degrees.

The price of cranes is very high, so that it can cost from several hundred million to several billion Tomans.

In construction projects, if the amount of work is small, many architects rent a tower crane, and if the project is relatively large, they buy a tower crane so that it is more economical.

The emergence of the tower crane

Since the tower crane is also a type of balance lever, it can be said that its creation and use happened by the ancient Greeks.

At that time, for construction projects, they used animals like donkeys to carry loads, and after a while they were able to make a device that has the power to carry loads like a donkey and the ability to rotate in place like a human.

Also, the Greeks used cranes in their harbors to increase speed.for loading ships and using them in construction, such as building stone towers. The first tower cranes were made of wood, but after the industrial revolution, tower cranes were made of cast iron, iron and steel.

Tower crane applications

Tower cranes usually provide the best combination of height and lifting capacity and are widely used in cases such as:

- Buildings Dams

- Towers and high buildings

- Dams

- Silo construction

- Cargo transportation in ports and customs

used They also have their own uses in other industries for example, in the transportation industry for loading and unloading, in the manufacturing industry for the assembly of heavy equipment, they are used in the construction industry to move materials..

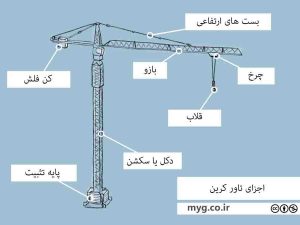

What are the parts of a tower crane?

Just as a balance lever consists of three parts, a tower crane also consists of three parts. 1- The central part that we call the base. 2- The part of the arm that is responsible for carrying the load. 3- The back part of the tower crane where concrete blocks are placed inside to balance the weight of the back and front of the tower..

Why don’t tower cranes fall?

For a tower crane, the issue of balance is very important, and in order to maintain its balance and endurance, its bases (fixing base) are placed in the ground and in concrete, just like a building, where its foundations are poured before starting construction.

Also, if needed, they maintain the balance of the tower crane by using balance belts to prevent it from falling. Also to maintain balance between the front arm The crane, which has the task of carrying and lifting the load, has an arm with concrete weights behind it to create a weight balance between the two sides of this giant lever.

During the initial installation of the tower crane, its stabilization base must be implemented in accordance with the required technical specifications specified in the manual of that particular type of tower crane, with the supervision and approval of the building engineer. Since it is not possible for the inspector to access this section and check the specifications during operation, the approval of the supervising engineer of the building will be required in this regard.

What are the types of tower crane models?

Many categories can be considered for tower cranes and each category is made for a specific group of needs. The three main categories of tower cranes are::

- Dimensions

- Installation model

- radius of motion

– 1 dimensions

Tower cranes are divided into two main categories, small and large, in terms of dimensions. Small tower cranes are designed for moving equipment and tools inside a small environment such as workshops, and large or giant tower cranes are used for building buildings and tall towers. Also another model. There is also one that is used in the oil industry to build oil tanks and move cargo in water and take things out of water, such as sunken ships, which is called a floating crane.

2– Installation model

In this model Cranes can be divided into two categories: 1- Self-installing 2- Installer help divided. As it is clear from their name, the self-installing tower crane does not need any helper for installation and setup, and it has the ability to increase or decrease its height. The most important feature of this crane is the possibility Quick and easy installation It is. Assisted tower cranes require an external and assisting agent such as a crane or even a helicopter (for very high heights) for installation and commissioning. And their height is increased by special height parts or sections. The characteristic of this category of tower cranes More power and height It is for carrying loads and moving objects.

.

– 3 moving beam

All cranes have a 360 degree movement radius or load displacement in the x and y axes Z. The movement radius means that what is the limit of a crane in these three axes? In this category, tower cranes can be divided into three categories: 1-fixed, 2-moving, and 3-rising.

Fixed tower cranes

As its name suggests, these types of tower cranes do not have any special features (unable to move and increase a certain height) and are used for normal applications.

Mobile tower cranes:

The most important characteristics of the mobile tower crane is its wide operational radius, that is, in the x and y axes which is land can move and work in different parts of a project. Of course, these tower cranes themselves are divided into three categories: 1- rail 2- road 3- floating and each has its own advantages and disadvantages..

For example, rail cranes

They move on a rail and can move as long as the rail is created for it. تاور کرین های جادهای ابعاد کوچکتری دارند و در حقیقت بیشتر شبیه جرثقیل هستند تا یک تاور ولی دارای مزیت نصب و راهاندازی بسیار سریع و حملونقل و جابهجایی گسترده هستند، و در عوض قدرت حمل بار کمتری نیز دارند .

Floating tower cranes, which we mentioned a little earlier, are used in the waters (bays and oceans) for the construction of oil mines or for taking out sunken ships.

Lifting cranes

Floating tower cranes, which we mentioned a little earlier, are used in the waters (bays and oceans) for the construction of oil mines or for taking out sunken ships. This crane model rises as the height of the building increases, and its strong point is its wide axis coverage z Is. This is the reason why this type of tower crane is used in the tower construction industry and the construction of skyscrapers and bridges..

What is the lifespan of a tower crane?

A tower crane can work for decades. For example, in our own country, Iran, we have tower cranes that were built 50 years ago and are still in use.

The reason is that these devices are mostly mechanical and the electrical parts can be updated. But in order for it to work properly, it needs to provide parts and regular services.

Tower crane parts

A tower crane consists of many physical and electronic parts, and we will continue to introduce all the important parts of the tower crane.

The most important parts of the crane are:

- Tower crane arrow or arm

- rotating part

- Operator cabin

- sugar head

- Pocket counter or flash can

- Chariot carriage

- Book or hook

- Engine house (electric motors and gearboxes)

- electrical panel

- electrical panel

- Stabilization base (types of shasti)

Advantages of using a tower crane

Ease of raising equipment and building materials

High displacement radius

The possibility of increasing the height of the tower crane

Having high security and protecting human lives

Ability to build towers and easy to scratch

Save money and time

.

1 . Arrow or tower crane arm:

The tower crane arm is also known as Flash or JIB The pocket is also said to carry the load. Using the arm, we can pick up the load from the ground and place it at a certain height. We can also move the load along the length axis.

The weight limit of the arm is that you can move a heavy load at the beginning of the arm’s length, but you cannot do this at the end of the arm’s length.

A very important point about the tower crane arm is that we cannot add too much load on it, otherwise we will cause an accident.

2 . Rotating part:

This part of the tower is used to hold the arm and the arm counter, and the towing wire of the hook system is also passed through this part. This part has a conical shape and is held by some towing wires or iron bars of the pocket and counter of the tower pocket. This piece is installed on top of the revolving system.

3. Operator cabin:

4. Sugar skull:

The tallest part of the tower crane, the sugar head of the tower crane, which is considered one of its height parts. The lower part of the sugar head is connected to the turret crane. This connection is generally done by screws

5. Flash can (pocket counter):

The end part of the tower is called a flash tower crane and in English it is called a counter jib. Of course, this part also has other names such as balance arm and tail. The arrow head is placed exactly in the opposite direction of the tower crane arrow or operating arm and its task is to maintain the balance of the tower crane. That is why the other name of this part is the balance arm. That is why the other name of this part is the balance arm. The type of weights used depends on the tonnage and lifting height of the tower crane.

6. Chariot carriage:

Chariot Tower Crane (chariot) is a part that is placed under the arrow. This piece is also known as Tower crane carriage. Also, because it is connected to the flash tower crane, it is called Trolley Jib in English. The task of the trolley is to carry the load in the horizontal direction. Chariot moves the load to the desired location by going back and forth.

7. Hook:

Tower crane hook (lifting hook) is a device used to catch and lift loads using devices such as hoists and cranes.

8. Gearboxes (electric motors):

The gearbox is one of the most important and at the same time the most practical part of the tower crane. The interface is used to increase the power of the engine for loading. Parts are needed for the hook, neck and carriage. Because if it is not, the engines should be much bigger, using that size and kilowatts of the engines will be lower and at the same time they will increase the output power of the engine that it gives us. The higher the output power of the gearboxes, the lower their speed ratio.

9. Switchboard (inverter):

The inverter panel is an intelligent control system in the field of tower cranes, which can help you experience better projects and enjoy the technology available in tower cranes. An inverter panel is a device that converts direct current into alternating current. This device can activate any frequency and voltage to be able to use them.

10. Altitude section:

These parts are used to increase the height of the tower crane. By being placed between height pieces, it opens the place of another height piece, and in this case, a new height piece can be added. This piece is naturally larger than the height pieces. Usually, in order to raise the height of the tower, it is necessary for the driver to have sufficient control over her position, so fences and corridors are installed around this part..

11. Stabilization base

Usually, these parts are different according to the type of tower crane bases. In fixed mode, these parts include bases that are placed in concrete or used in mobile carriages..